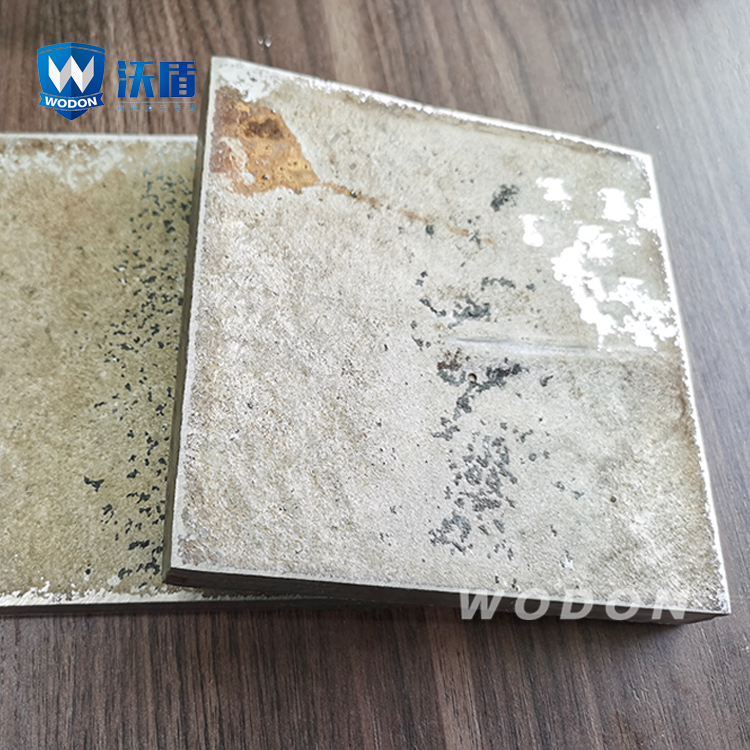

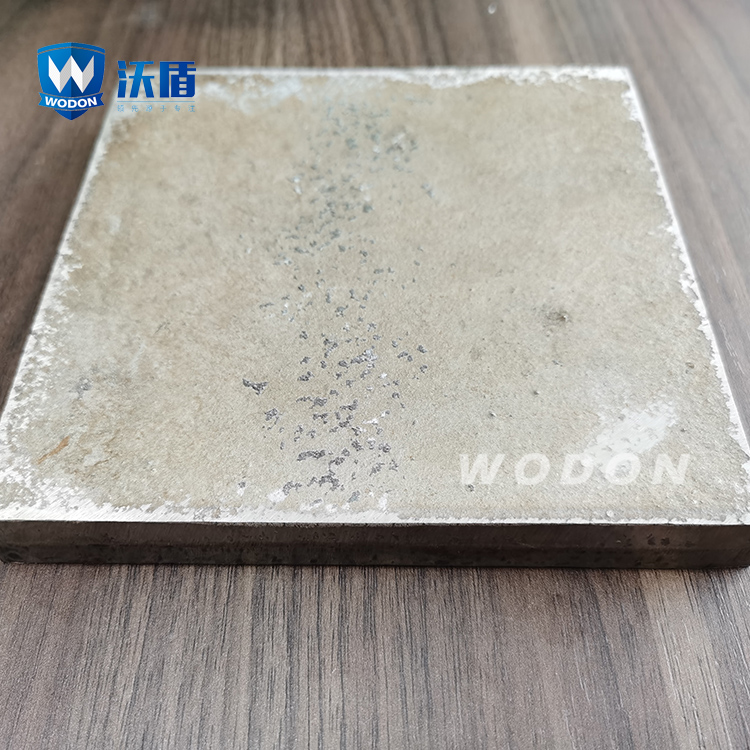

I-WD-M3 Indawo ebushelelezi

I-Smooth Surface

I-Chromium Carbide Overlay Plate

I-ADVANTAGE:

* Indawo ebushelelezi, imbongolo yokudlula eyodwa, Abukho ubuhlalu obushisela phezulu

* I-microstructure engaguquki nobulukhuni kuze kufike kumugqa wokuhlanganisa

* Ukusebenza ngokubambisana okuphansi

* Izakhiwo ezinhle kakhulu zokuhuzuka kanye nomthelela

* Izinga lokushisa lokusebenza <600℃

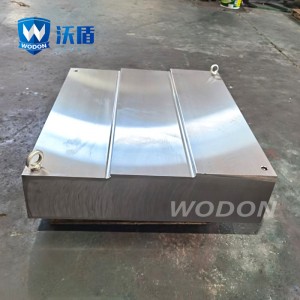

* Ongakukhetha kokumbondelana okuhlukile okungewona uzibuthe

* Itholakala emshinini wokugaywa kanye nendawo epholishwe ngaphambili

OKUJWAYELEKILEIZINGA LEZOBUCHWEPHESHE

| Ibanga | Ukwakheka kwamakhemikhali | |||||||

|

| C | Cr | Mn | Si | B | S | P | Nb+Mo+Ti+V+W |

| I-WD-M3 | 2.0-5.0 | 18-35 | <1.5 | <1.2 | <0.6 | <0.033 | <0.033 | <1.5 |

| I-WD-M7 | 2.0-5.0 | 18-28 | <1.5 | <1.2 | <0.4 | <0.033 | <0.033 | 7-10 |

| Izakhi Eziyisisekelo | I-WD-M3 | I-WD-M7 |

| Izinto eziyisisekelo | Q235B | Q235B |

| Isigaba esiqinile se-alloy | I-Chromium carbide | I-Chromium carbide + Composite carbide |

| Ivolumu ye-carbide eyinhloko (%) | >37 | >37 |

| Ukuqina Kwembondela nge-HV (HRC) | 670 (58) | 670 (58) |

| Ukuhlolwa kokuhuzuka kwesondo lerabha ngesihlabathi esomile (g) | <0.15g | <0.14g |

| Ukuhlolwa kokuhuzuka komthelela (g) | <0.10g | <0.08g |

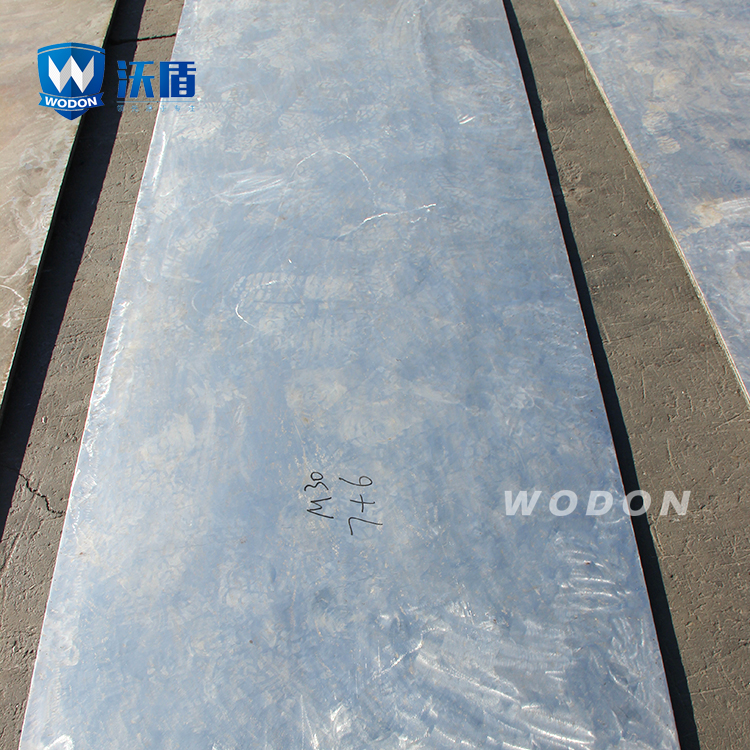

| Ubukhulu obujwayelekile (mm) | 5/5, 6/7, 8/9, 10/11, 12/11, 17/11 | 17/11, 20/11, 24/13 |

| Usayizi wepuleti ojwayelekile (mm) | 1000*3000, 600*3000 | 600*3000 |

| Isicelo esinconyiwe | Ukuhuzuka okuvamile | Ukuhuzuka okwedlulele |