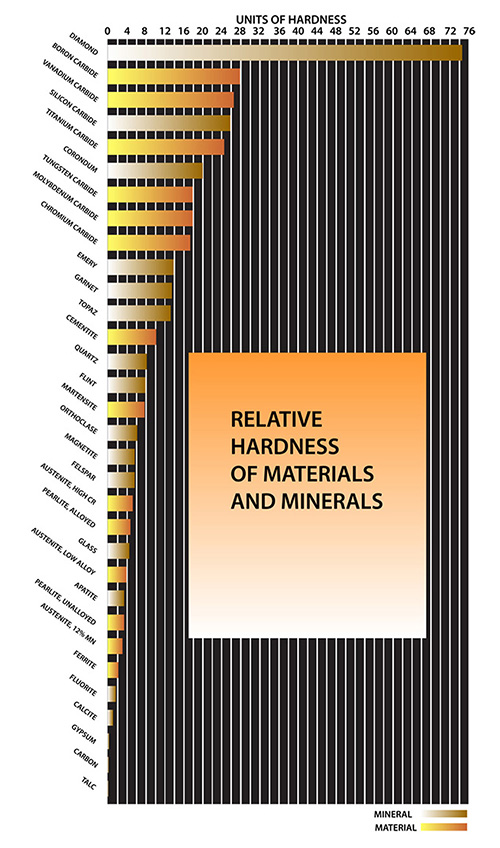

Ubulukhuni obuhlobene Bezinto Zokusebenza kanye Nezimbiwa

-

- 1. Idayimane

- 2. I-Boron carbide

- 3. Vanadium carbide

- 4. I-silicon carbide

- 5. I-Titanium carbide

- 6. Corundum

- 7. I-Tungsten carbide

- 8. I-Molybdenum carbide

- 9. I-Chromium carbide

- 10.Emery

- 11. I-Garnet

- 12. Itopazi

- 13. Usimende

- 14. I-quartz

- 15. Flint

- 16. I-Martensite

- 17. I-Orthoclase

- 18. Umazibuthe

- 19. Felspar

- 20. Austenite, High CR

- 21. I-Pearlite, i-Alloyed

- 22. Ingilazi

- 23. I-Austenite, i-alloy ephansi

- 24. Apatite

- 25. Pearlite, Unalloyed

- 26. Austenite, 12% Mn

- 27. I-Ferrite

- 28. I-Fluorite

- 29. Calcite

- 30. Gypsum

- 31. Ikhabhoni

- 32. Talc

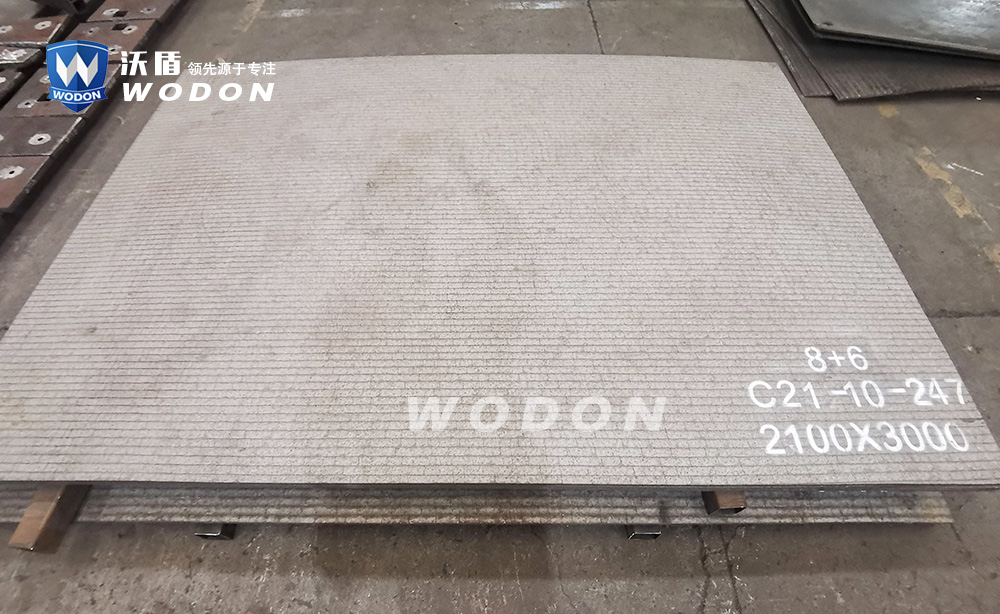

- Wodon zikhethekile ekukhiqizeni i-Chromium carbide overlay wear plate, sisebenzisa ubuchwepheshe bokushisela be-arc obungaphansi kwamanzi obuqukethe okuqukethwe kwe-Cr okwengeziwe okusuka ku-25% kuya ku-45%. ingxenyenamba yevolumu ye-carbide ku-microstructure ingaphezu kuka-50% futhi ubulukhuni obukhulu bezinhlayiya eziqinile yi-HV1800. indlela ye-ASTM-G65 A ingaphansi kuka-0.16g.

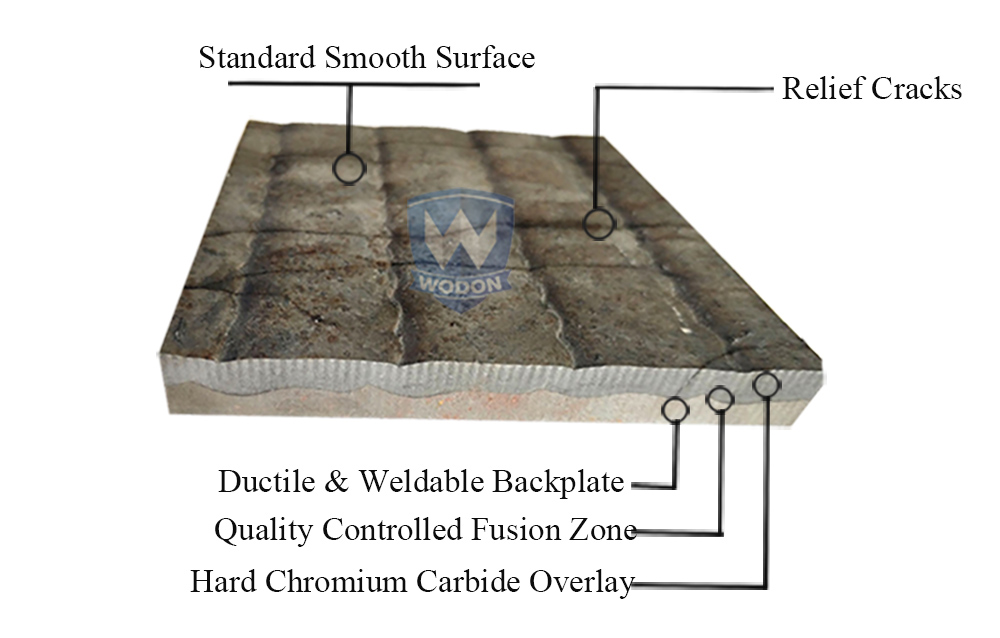

- I-Chromium Carbide bimetallic plate:

- Maphakathi/Low carbon steel +Aizendlalelo ezimelana ne-brasion →CI-hromium carbide bimetallic plate ene-metallurgical bonding

- (Q235/Q345B + Imbondela ye-Chromium Carbide →CI-hromium carbide bimetallic plate nge-arc engaphansi kwamanzi noma i-Open arc welding

- ubuchwepheshe)

- Imininingwane:

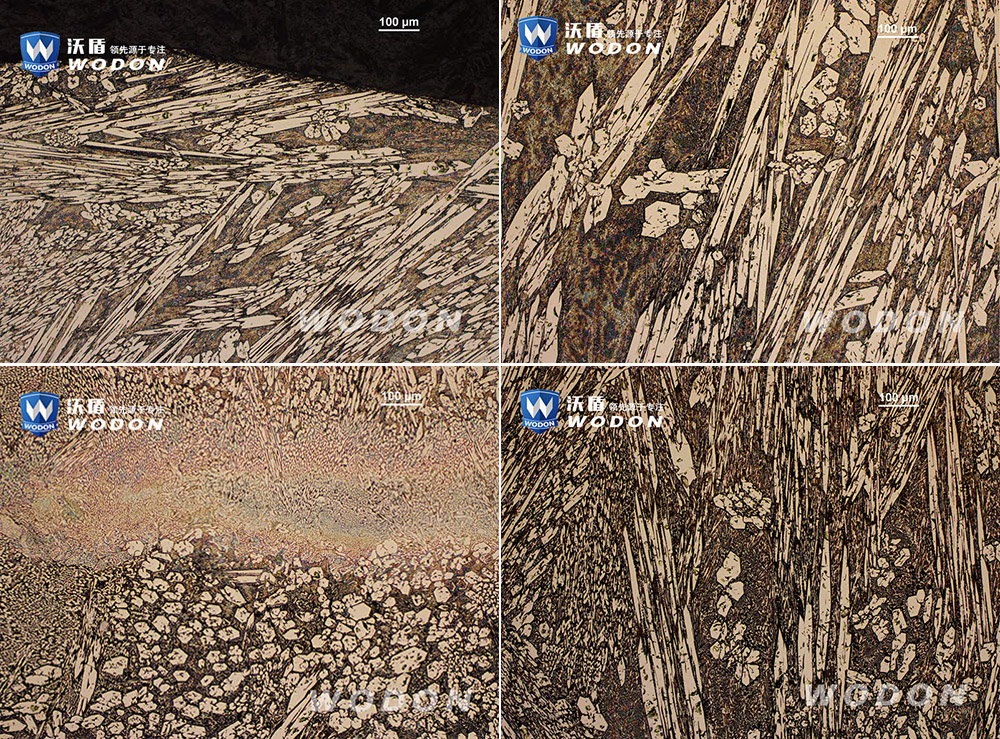

- Isendlalelo esimelana nokuguga sinenani eliphezulu lezinhlayiya eziqinile ze-chromium carbide. Lezi zinhlayiya zisakazwa ngokulinganayo kulo lonke ungqimba, zakha i-microstructure eqinile. Ukuqina yi-HRC 58~65futhi kuya ngogqinsi lwembondela.

- Izithako eziyinhloko ze-Wodon plate yi-C(%): 3.0~6.0 kanye ne-Cr(%): 25~45. Lesi silinganiso samakhemikhali siphumela enanini elikhulu lezinhlayiya eziqinile ze-Cr7C3 chrome carbide. Ubulukhuni obuncane (kufika ku-HV1800) balezi zinhlayiya kulo lonke ungqimba kuzoqinisekisa indawo ekwazi ukumelana nokuguga.

- Imbondela ne-base plate ziyi-metallurgical bonding. Imbondela izongena ku-base plate cishe ngo-0.8~1.8 mm, ifinyelele ku-350 Mpa ekuhlolweni kwethu.

-

- I-WD1200 yokugqoka ipuletiingasetshenziselwa i-abrasion applica enamandlations.

- * Isembozo se-Chromium carbide sigqoka ipuleti elingazweli

- * Ngobuchwepheshe bokushisela be-arc obungaphansi kwamanzi

- * Ukwakhiwa Kwekhemikhali: C: 3.0-6.0% Cr: 25-45%

- * Ingxenye yevolumu yeChromium carbide Cr7C3 cishe ngama-50%

- * Ugqinsi longqimba olumelana nokugqoka lungafinyelela ku-50 mm

- * Ukumelana nokushisa kufika ku-600°C

- * I-Lager standard resistant wear wear 1400*3000mm, 1400*3500mm, 2100*3500mm

- * Ubucaba obungcono obunobuso obushelelezi

- * Ukuqina: HRC58-65(650-720HV)

- Lawa mapuleti asetshenziswa kakhulu eMining, Cement, Power, Coal, Port, Wind turbines and Metallurgical industry..

-

Isikhathi sokuthumela: Sep-27-2021