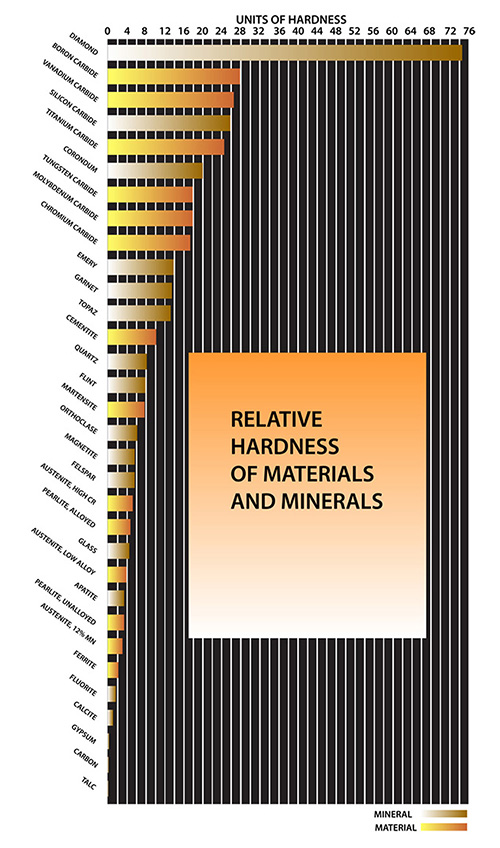

Ubulukhuni obuhlobene bezinto zokwakha namaminerali

-

- 1. IDayimane

- 2. I-Boron carbide

- 3. I-vanadium carbide

- 4. Silicon khabhayithi

- 5. I-titanium carbide

- 6. ICorundum

- 7. I-Tungsten carbide

- 8. I-Molybdenum carbide

- 9. I-chromium carbide

- 10. Emery

- 11. Igarnet

- 12. ITopazi

- 13. Isamente

- 14. Quartz

- I-Flint

- 16. IMartensite

- 17. I-Orthoclase

- 18. Magnetite

- 19. UFelspar

- 20. I-Austenite, High CR

- 21. Pearlite, Allied

- 22. Ingilazi

- 23. I-Austenite, ingxubevange ephansi

- 24. Apatite

- 25. Pearlite, Abangasebenzi

- 26. I-Austenite, i-12% Mn

- 27. Ferrite

- 28. I-Fluorite

- 29. I-Calcite

- 30. IGypsum

- 31. Ikhabhoni

- 32. UThalikhi

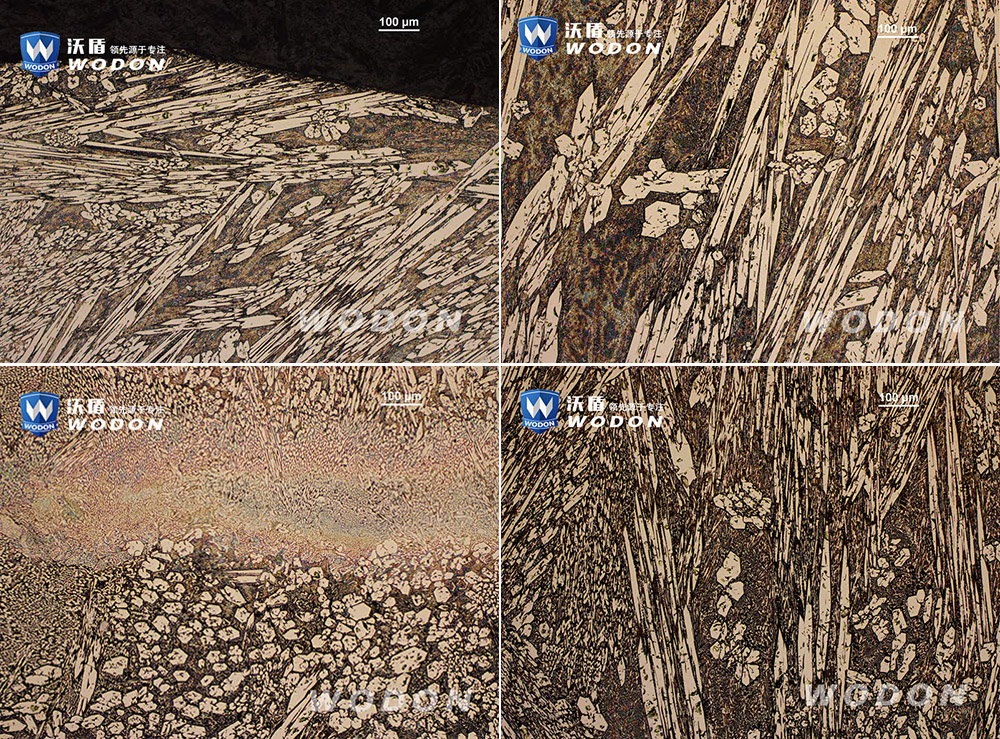

- UWodon zikhethekile ekukhiqizeni i-chromium carbide imbondela yokugqoka ipuleti, sisebenzisa i-arc welding technoloy ecwilisiwe equkethe okuqukethwe okuningi kwe-Cr kusuka ku-25% kuye ku-45%. ingxenyenamba yevolumu ye-carbide ku-microstructure ingaphezu kwama-50% nobulukhuni obukhulu bezinhlayiya eziqinile yi-HV1800. i-ASTM-G65 methode A ingaphansi kuka-0.16g.

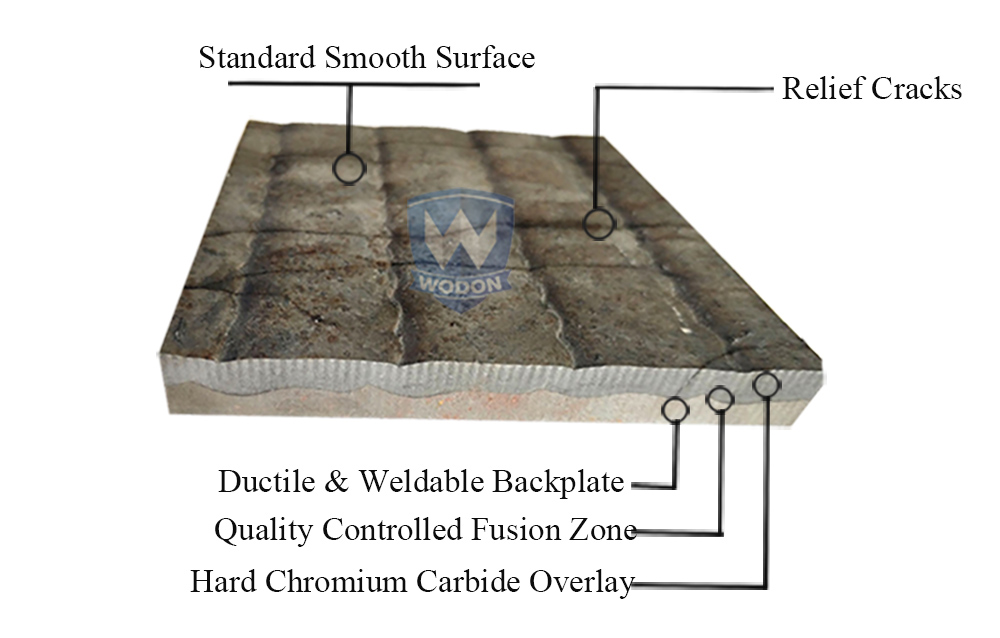

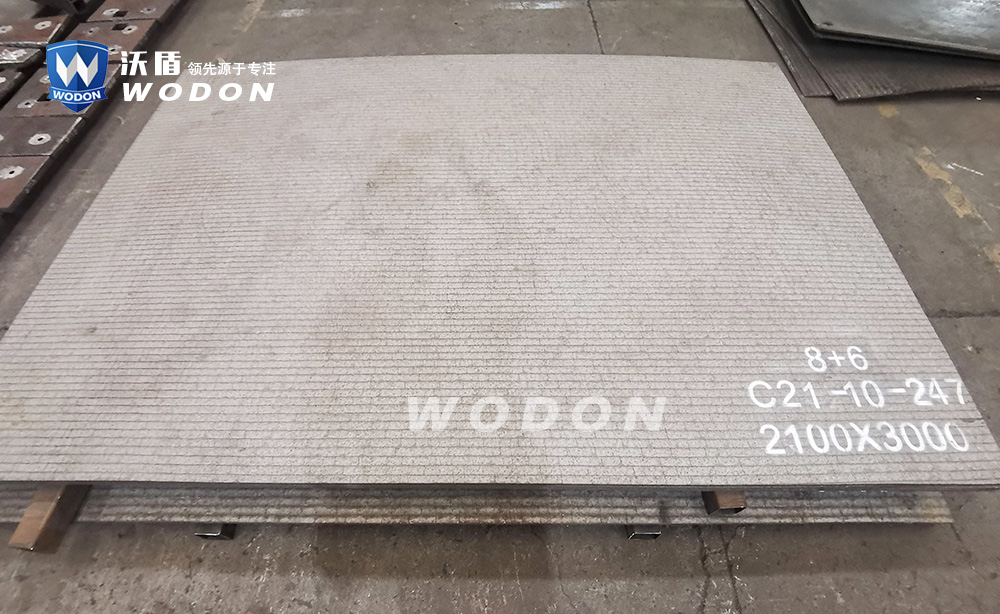

- Ipuleti le-bimetallic le-Chromium Carbide:

- Okulingene /Li-ow carbon steel + Aizingqimba ezingamelana nezimboni → Chromium carbide ipuleti bimetallic ne kunenze nisondelane metallurgical

- (Q235 / Q345B + Imbondela yeChromium Carbide → Ci-hromium carbide ipuleti le-bimetallic nge-submersed arc noma i-Open arc welding

- ubuchwepheshe)

- Imininingwane:

- Isendlalelo sokumelana nokugqoka sinenani eliphakeme lezinhlayiya ezinzima ze-chromium carbide. Lezi zinhlayiya zisatshalaliswa ngokulinganayo kulo lonke ungqimba, zakha ukwakheka okuqinile kwe-microstructure. Ubulukhuni yi-HRC 58~ 65 futhi kuya ngosayizi wembondela.

- Izithako eziyinhloko zepuleti leWodon yi-C (%): 3.0 ~6.0 no-Cr (%): 25 ~ 45. Lesi silinganiso samakhemikhali siphumela enanini elikhulu lezinhlayiya ezinzima ze-Cr7C3 chrome carbide. Ubulukhuni obuncane (kuze kufike ku-HV1800) balezi zinhlayiya kulo lonke ungqimba kuzoqinisekisa indawo emelana nokugqokwa okuhle kakhulu.

- Imbondela nesisekelo sepuleti kungumbhoshongo wensimbi. Imbondela izongena ku-base plate cishe ngo-0.8 ~ 1.8 mm, ifinyelele kuma-350 Mpa ezivivinyweni zethu.

-

- WD1200 bafake ipuleti ingasetshenziselwa ukufaka isicelo esinzima sokulimalations.

- * I-Chromium carbide imbondela gqoka ipuleti elingazweli

- * Ngobuchwepheshe bokucwilisa be-arc ocwilisiwe

- * Ukwakhiwa kwamakhemikhali: C: 3.0-6.0% Cr: 25-45%

- * Ingxenyenamba yevolumu ye-Chromium carbide Cr7C3 cishe ngo-50%

- * Ubukhulu besendlalelo esimelana nokugqoka bungafinyelela ku-50 mm

- * Ukumelana nokushisa kuze kufike ku-600 ° C

- * Indawo emelana nokugqoka ejwayelekile engu-1400 * 3000mm, 1400 * 3500mm, 2100 * 3500mm

- * Flatness Better nge ebusweni bushelelezi

- * Ubulukhuni: HRC58-65 (650-720HV)

- Lezi zingcwecwe zisetshenziswa kakhulu kwezimayini, usimende, amandla, amalahle, imbobo, imishini yomoya kanye nomkhakha weMetallurgical.

-

Isikhathi Iposi: Sep-27-2021