Kungani i-wear plate yethu inokumelana nokugqokwa okuhle kangaka?

1. Ukwakheka kwamakhemikhali ayimbondela kuyisihluthulelo.

Izithako eziyinhloko zamapuleti e-Wodon ngu-C(%) :3.0-5.0 kanye no-Cr(%):25-40.

Lesi silinganiso samakhemikhali siphumela enanini elikhulu lezinhlayiya eziqinile ze-Cr7C3 chrome carbide. I-micro-hardness (kufika ku-HV1800)zaleziizinhlayiya kulo lonke ungqimba zizoqinisekisa indawo ekwazi ukumelana nokugqoka okuphezulu.

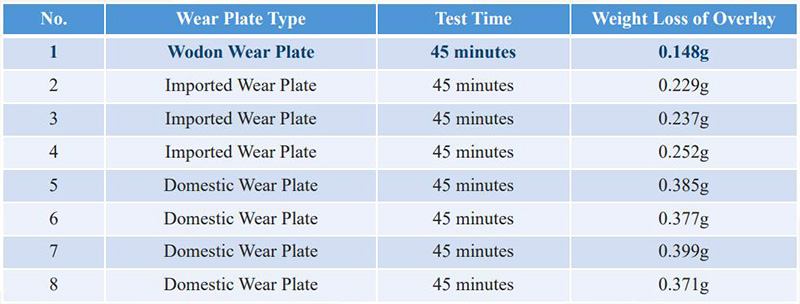

Ukuhlolwa kokusebenza:

Imishini yokuhlola: Isondo lerabha lesihlabathi se-quartzumshini wokuhlola i-abrasion.

Izimo: 1. Ukukhetha izibonelo zobukhulu obufanayo bezinto ezihlukene kanye nabakhiqizi bamapuleti okugqoka, bese uwabekangaphansi kwezimo zokusebenza ezifanayo zokugqoka emishinini yethu yokuhlola.

2.Imizuzu engama-45 yesifanekiso ngasinye

Imizuzu engama-45 yesifanekiso ngasinye

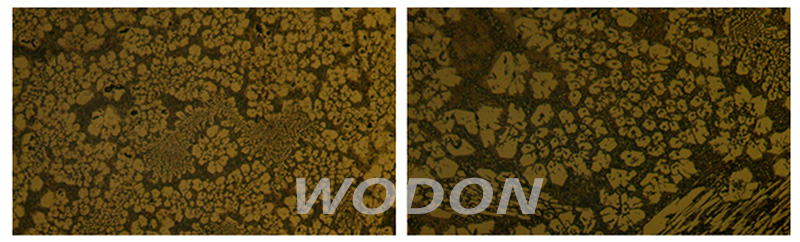

2. I-Chromium carbide microstructure

Ukumelana nokugqokwa kwepuleti lokugqoka kuncike kakhulu ebukhuni, ukuma, usayizi, inani kanye nokusatshalaliswa kwe-chromium.izinhlayiya ze-carbide ezinzima.

Njengoba ungabheka esithombeni, ingxenye yevolumu ye-carbide (Cr7C3) ku-microstructure ingaphezu kuka-50%.

3. Amandla okubopha phakathi kwembondela ne-base plate.

I-overlay ne-base plate ihlangana kahle kakhulu. Imbondela izongena ku-base plate cishe ngo-0.8mm-1.8mm, ifinyelelekufika ku-350Mpa ekuhlolweni kwethu.

Isikhathi sokuthumela: Aug-16-2021