Insimbi engagqwali inikeza izinzuzo eziningi zezinto ezibonakalayo kuhlu lwezinhlelo zokusebenza zezimboni, kodwa indlela yokwenza imishini ekhethiwe ingathinta ikhwalithi nobuqotho bezingxenye ezenziwe ngale nsimbi esebenza ngezindlela eziningi.

Lesi sihloko sihlola umqondo wokusetshenziswa kwensimbi engagqwali kuhlu lwezingxenye nama-assemblies, futhi sibheka indima ye-photochemical etching njengobuchwepheshe bokucubungula obungenza ukukhiqizwa kwemikhiqizo esetshenziswayo emisha nenembayo ephezulu.

Kungani ukhetha insimbi engagqwali?Insimbi engagqwali empeleni iyinsimbi ethambile enokuqukethwe kwe-chromium okungu-10% noma ngaphezulu (ngesisindo).Ukwengezwa kwe-chromium kunikeza insimbi izici zayo eziyingqayizivele zensimbi engagqwali, ukumelana nokugqwala.Okuqukethwe kwe-chromium kwensimbi ivumela ukwakheka kwefilimu ye-chromium oxide eqinile, enamathelayo, engabonakali, engagqwali endaweni yensimbi.Uma ilimele ngomshini noma ngamakhemikhali, ifilimu ingakwazi ukuzilungisa, inqobo nje uma umoya-mpilo ukhona (ngisho namanani amancane kakhulu).

Ukumelana nokugqwala nezinye izinto eziwusizo zensimbi zithuthukiswa ngokwandisa okuqukethwe kwe-chromium nokwengeza ezinye izakhi ezifana ne-molybdenum, i-nickel ne-nitrogen.

Insimbi engagqwali inezinzuzo eziningi.Okokuqala, into ekwazi ukumelana nokugqwala, futhi i-chromium iyingxenye ye-alloying enikeza insimbi engagqwali le khwalithi.Amamaki e-alloy aphansi amelana nokugqwala endaweni esemkhathini namanzi ahlanzekile; amamaki e-alloy aphezulu amelana nokugqwala kwe-asidi eminingi, izixazululo ze-alkaline, nasezindaweni ezine-chlorine, okwenza izakhiwo zabo zibe usizo ekucubunguleni izitshalo.

Amamaki akhethekile aphezulu e-chromium ne-nickel alloy amelana nokukala futhi alondoloze amandla aphezulu emazingeni okushisa aphezulu.Insimbi engagqwali isetshenziswa kakhulu kuma-heaters, ama-superheaters, ama-boilers, ama-feedwater heater, ama-valve namapayipi ajwayelekile, kanye nasezindizeni nasezinsizeni zokusebenza zasemkhathini.

Ukuhlanza nakho kuyindaba ebaluleke kakhulu.Ikhono lensimbi engagqwali lokuhlanzwa kalula likwenze kwaba yisinqumo sokuqala ezimweni eziqinile zenhlanzeko njengezibhedlela, amakhishi nezindawo zokucubungula ukudla, kanye nesiphetho esikhanyayo esilula ukusigcina sensimbi engagqwali sihlinzeka ngesimanjemanje futhi esikhangayo. ukubukeka.

Okokugcina, lapho kucutshungulwa izindleko, kucatshangelwa izindleko zempahla nezindleko zokukhiqiza kanye nezindleko zomjikelezo wokuphila, insimbi engagqwali ivamise ukuba iyona ndlela eshibhe kakhulu yezinto ezibonakalayo futhi ingaphinda isetshenziswe ngo-100%, iqedele wonke umjikelezo wokuphila.

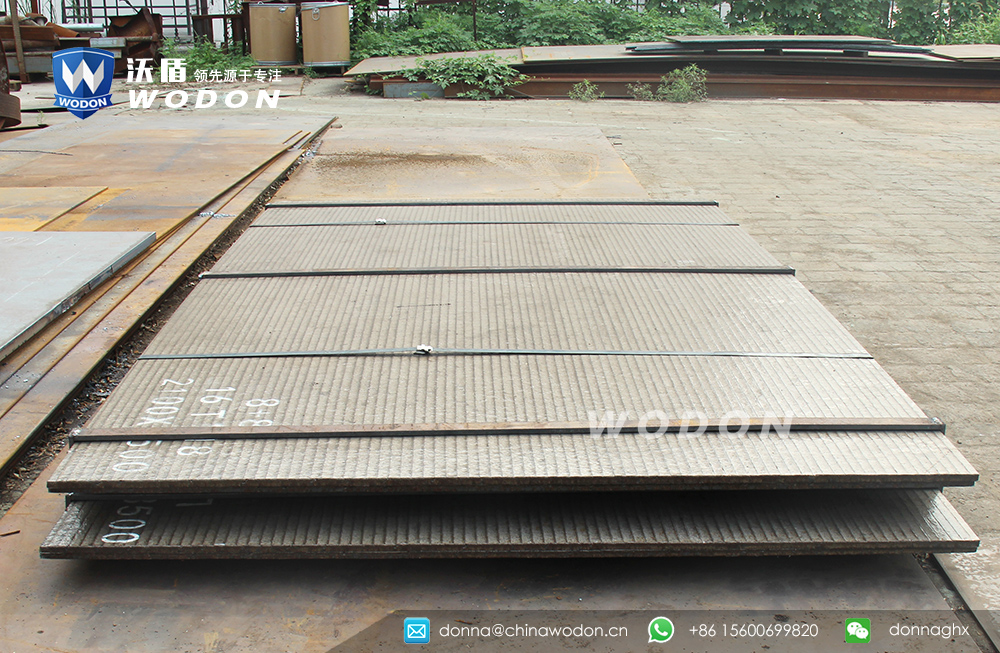

"Amaqembu e-etch" ensimbi afakwe ngesithombe amakhemikhali (okuhlanganisa i-HP Etch kanye ne-Etchform) aqopha izinhlobonhlobo zezinsimbi ezinembayo ezingenakuqhathaniswa nanoma yikuphi emhlabeni.Amashidi acutshunguliwe namafoyili ahluka ngogqinsi ukusuka ku-0.003 kuya ku-2000 µm. Nokho, insimbi engagqwali ihlala ingeyokuqala ukukhetha kumakhasimende amaningi enkampani ngenxa yokuguquguquka kwayo, ubuningi bamamaki atholakalayo, inani elikhulu lama-alloys ahlobene, izinto ezibonakalayo ezithandekayo (njengoba kuchazwe ngenhla), kanye nenani elikhulu lokuqedwa.Kuyinsimbi yokuzikhethela kwabaningi. izinhlelo zokusebenza ezinhlotsheni eziningi zezimboni, ezisebenza ngomshini 1.4310: (AISI 301), 1.4404: (AISI 316L), 1.4301: (AISI 304) nezinsimbi ezincane zezinsimbi ze-austenitic ezaziwayo, i-ferritic ehlukahlukene, i-ma Tensitic288 Mo1. /7C27Mo2) noma izinsimbi eziyi-duplex, i-Invar ne-Alloy 42.

I-Photochemical etching (ukukhishwa okukhethekile kwensimbi kusetshenziswa imaski ye-photoresist ukuze kukhiqizwe izingxenye ezinembayo) kunezinzuzo ezimbalwa ezingokwemvelo ngaphezu kwamasu okwenziwa kwensimbi yeshidi elivamile.Okubaluleke kakhulu, ukushumeka kwe-photochemical kukhiqiza izingxenye kuyilapho kuqeda ukuwohloka kwempahla ngoba akukho kushisa noma amandla asetshenziswayo phakathi nokucubungula. ngaphezu kwalokho, inqubo ingakhiqiza cishe izingxenye eziyinkimbinkimbi ngokungapheli ngenxa yokususwa ngesikhathi esisodwa kwezici zengxenye kusetshenziswa i-etchant chemistry.

Amathuluzi asetshenziselwa ukushumeka awedijithali noma ingilazi, ngakho-ke asikho isidingo sokuqala ukusika isikhunta sensimbi esibizayo futhi okunzima ukusifaka.Lokhu kusho ukuthi inani elikhulu lemikhiqizo lingenziwa kabusha ngaphandle kokugqokwa kwamathuluzi angenaziro, ukuqinisekisa ukuthi eyokuqala futhi izingxenye eziyizigidi ezikhiqizwayo ziyefana.

Amathuluzi edijithali nawengilazi nawo angalungiswa futhi ashintshwe ngokushesha kakhulu nangokwezomnotho (imvamisa phakathi kwehora), awenze alungele ukwenza i-prototyping kanye nokusebenza kokukhiqiza kwevolumu ephezulu.Lokhu kuvumela ukulungiselelwa komklamo “okungenangozi” ngaphandle kokulahlekelwa ngokwezimali.Isikhathi sokuguqula singu ilinganiselwa ku-90% ngokushesha kunezingxenye ezinezitembu, ezidinga ukutshalwa kwezimali okubalulekile kwangaphambili ekusetshenzisweni kwamathuluzi.

Izikrini, Izihlungi, Izikrini kanye Nokugoba Inkampani ingaqopha uhla lwezingxenye zensimbi engagqwali ezihlanganisa izikrini, izihlungi, izikrini, iziphethu eziyisicaba kanye nemithombo yokugoba.

Izihlungi nezisefo ziyadingeka emikhakheni eminingi yezimboni, futhi amakhasimende avame ukudinga imingcele yobunkimbinkimbi kanye nokunemba ngokwedlulele.Inqubo yokufaka izithombe ze-photochemical ye-micrometal isetshenziselwa ukukhiqiza uhla lwezihlungi nezikrini zemboni ye-petrochemical, imboni yokudla, imboni yezokwelapha kanye imboni yezimoto (izihlungi ezithwebule izithombe zisetshenziswa ezinhlelweni zokujova uphethiloli kanye nama-hydraulics ngenxa yamandla azo aqinile) .I-micrometal ithuthukise ubuchwepheshe bayo bokufaka amakhemikhali ezithombe ukuze ivumele ukulawulwa okunembile kwenqubo yokufaka ngezilinganiso ezi-3. Lokhu kusiza ukudalwa kwamajiyometri ayinkimbinkimbi futhi, uma isetshenziswa ekwakhiweni kwamagridi kanye nezisefo, inganciphisa kakhulu izikhathi zokuhola.Ukwengeza, izici ezikhethekile kanye nokubunjwa okuhlukahlukene kokuvula kungafakwa kugridi eyodwa ngaphandle kwezindleko ezikhulayo.

Ngokungafani nezindlela zendabuko zokwenza imishini, i-photochemical etching inezinga eliphakeme lokuyinkimbinkimbi ekukhiqizeni ama-stencil amancane nanembile, izihlungi kanye nezisefo.

Ukususwa ngesikhathi esisodwa kwensimbi ngenkathi i-etching kunika amandla ukuhlanganiswa kwamajiyometri wezimbobo eziningi ngaphandle kokuhlangabezana nezindleko ezibizayo zokusebenzisa amathuluzi noma umshini, futhi amameshi aqoshiwe awabizi futhi awanawo ukucindezeleka ngokonakaliswa kwezinto lapho amapuleti anezimbobo ethambekele ekuwohlokeni kweqanda.

Ukufakwa kwamakhemikhali ezithombe akuguquli ukuphela kwento ecutshungulwayo futhi akusebenzisi ukuthintana kwensimbi kuya kwensimbi noma imithombo yokushisa ukuze kuguqulwe izici ezingaphezulu.Ngenxa yalokho, inqubo inganikeza isiphetho esiyingqayizivele sobuhle obuphezulu ensimbi engagqwali, okwenza kufanelekile izicelo zokuhlobisa.

Izingxenye zensimbi engagqwali ezifakwe ngezithombe nazo zivame ukusetshenziswa ekusetshenzisweni kwemvelo okubucayi noma okweqisayo - njengamasistimu amabhuleki e-ABS namasistimu omjovo kaphethiloli - futhi ukugoba okugxiliwe "kungagoba" ngokuphelele izigidi zezikhathi ngoba inqubo ayiguquli amandla okukhathala. yensimbi .Ezinye izindlela zokwenza imishini ezinjengokwenza imishini kanye nokwenza umzila ngokuvamile zishiya ama-burrs amancane nezingqimba zokusakaza kabusha ezingase zibe nomthelela ekusebenzeni kwentwasahlobo.

I-Photochemical etching iqeda izingosi zokuphuka ezingase zibe khona ohlamvini olubalulekile, ikhiqize ukugoqa kwesendlalelo esinganaburr kanye ne-recast, iqinisekisa impilo ende yomkhiqizo nokuthembeka okuphezulu.

Insimbi Efingqiwe nensimbi engagqwali inezinhlobonhlobo zezakhiwo ezizenza zilungele izinhlelo zokusebenza eziningi ze-pan-industrial.Nakuba kubonwa njengento elula uma kuqhathaniswa ukuthi icutshungulwe ngamasu okudala eshidi lensimbi, i-photochemical etching inikeza abakhiqizi izinzuzo ezibalulekile lapho bekhiqiza inkimbinkimbi nezokuphepha ezibucayi. izingxenye.

I-Etching ayidingi ukufakwa kwamathuluzi aqinile, ivumela ukukhiqizwa okusheshayo kusuka ku-prototype kuya ekukhiqizeni umthamo ophezulu, inikeza ingxenye eyinkimbinkimbi engenamkhawulo, ikhiqiza izingxenye ezingenasici kanye ne-stress-free, ayithinti ukufudumala kwensimbi nezakhiwo, isebenza kuwo wonke amabanga ensimbi, futhi ifinyelela Ukunemba. ka ±0.025 mm, zonke izikhathi zokuhola zingezinsuku, hhayi izinyanga.

Ukuguquguquka kwenqubo yokufaka amakhemikhali ezithombe kwenza kube ukukhetha okuphoqelelayo ekwenzeni izingxenye zensimbi engagqwali ezindaweni eziningi eziqinile, futhi kuvuselela ukuqanjwa kabusha njengoba kususa imigoqo etholakala kumasu okwenziwa kwensimbi eshidi konjiniyela abaklami.

Into enezakhiwo zensimbi futhi ehlanganisa izakhi zamakhemikhali ezimbili noma ngaphezulu, okungenani eyodwa yazo eyinsimbi.

Ingxenye ye-filamentous yezinto ezakha emaphethelweni ocezu lokusebenza ngesikhathi somshini.Imvamisa ibukhali.Ingasuswa ngamafayela esandla, amasondo okugaya noma amabhande, amasondo ocingo, amabhulashi e-fiber abrasive, okokusebenza kwejethi yamanzi, noma ezinye izindlela.

Ikhono le-alloy noma impahla ukumelana nokugqwala nokugqwala.Lezi yizici ze-nickel ne-chromium ezakhiwe ngama-alloys njengensimbi engagqwali.

Into eholela ekuqhekekeni ngaphansi kwengcindezi ephindaphindwayo noma eguquguqukayo enenani eliphakeme elingaphansi kwamandla aqinile wezinto ezibonakalayo. Ukuphuka kokukhathala kuqhubeka, kuqala ngemifantu emincane ekhula ngaphansi kwengcindezi eguquguqukayo.

Ukucindezeleka okukhulu okungagcinwa ngaphandle kokwehluleka kwenani elicacisiwe lemijikelezo, ngaphandle uma kuchazwe ngenye indlela, ukucindezeleka kuhlehliswa ngokugcwele ngaphakathi komjikelezo ngamunye.

Noma iyiphi inqubo yokukhiqiza lapho insimbi isetshenziswa khona noma yenziwe ngomshini ukuze kunikeze ucezu lomsebenzi isimo esisha.Ngokubanzi, leli gama lihlanganisa izinqubo ezifana nokuklama nokwakheka, ukwelashwa kokushisa, ukuphatha impahla kanye nokuhlola.

Insimbi engagqwali inamandla amakhulu, ukumelana nokushisa, ukusebenza kahle kakhulu kwemishini kanye nokumelana nokugqwala.Izigaba ezine ezijwayelekile zenzelwe ukumboza uhla lwezakhiwo zemishini nezomzimba zezinhlelo ezithile zokusebenza.Amamaki amane yilawa: CrNiMn 200 series kanye ne-CrNi 300 series type austenitic; uhlobo lwe-chromium martensitic, uchungechunge oluqinile lwe-400; i-chromium, uhlobo lwe-ferritic lwechungechunge olungaqinile lwe-400; Ama-alloys e-chromium-nickel aqina ukujuluka anezici ezengeziwe zokwelashwa kwesixazululo nokuqina kweminyaka.

Esivivinyweni esiqinile, isilinganiso somthwalo omkhulu endaweni enqamula ingxenye yokuqala.Futhi ibizwa ngokuthi amandla okugcina.Qhathanisa namandla esivuno.

Isikhathi sokuthumela: Jul-22-2022